When it comes to professional snooker tables, one specification stands above all others:

45mm slate thickness.

If you are a snooker table manufacturer, distributor, or project contractor, understanding the technical standards of 45mm snooker slate is essential for delivering tournament-level performance.

This guide explains:

- Why 45mm is the global standard for 12ft snooker tables

- Technical specifications of professional snooker slate

- Flatness tolerance and density requirements

- 5-piece slate structure design

- Installation and seam treatment

- How to evaluate a high-quality supplier

1. Why 45mm Slate Is Standard for 12ft Snooker Tables

A full-size snooker table measures:

- 12ft × 6ft playing surface

- Total slate weight: 900–1100 kg

- Typically 5-piece construction

Because of the table’s large span, thinner slate (25mm–30mm) is structurally insufficient.

Engineering Reasons for 45mm Thickness

✔ Prevents deflection across long spans

✔ Supports uniform load distribution

✔ Maintains flatness under frame stress

✔ Ensures long-term structural stability

✔ Meets tournament certification requirements

For professional competitions, 45mm is not optional — it is required.

2. Technical Specifications of Professional 45mm Snooker Slate

Below are standard technical parameters used in high-end manufacturing:

Thickness Tolerance

- 45mm ± 0.2mm

Surface Flatness

- ± 0.1mm across entire panel

- Checked with precision straight edge

Density

- Typically 2.7–2.8 g/cm³

- High density ensures vibration absorption

Surface Finish

- Precision ground

- Smooth, uniform texture

- No polishing gloss (cloth adhesion required)

Moisture Content

- Naturally stable

- Low absorption rate

Consistency across all 5 pieces is critical.

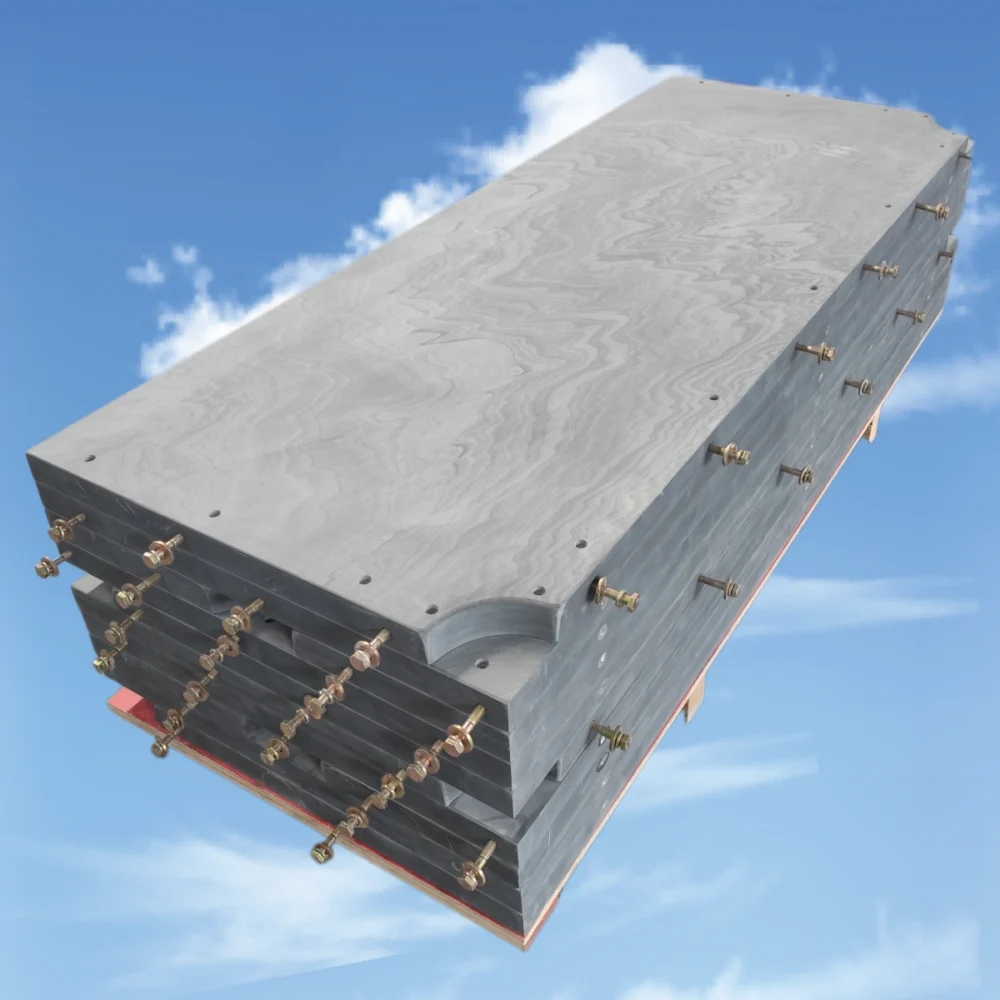

3. Five-Piece Slate Structure for 12ft Snooker Tables

Professional 12ft snooker tables use a 5-piece slate system.

Why 5 Pieces?

- Easier transport and installation

- Reduced breakage risk

- Controlled structural alignment

- Better weight distribution

Each piece is precision-cut and CNC-machined for:

- Pocket openings

- Rail bolt holes

- Alignment positioning

Accurate seam alignment is essential for perfect ball roll.

4. Flatness Control: The Core of Professional Performance

In snooker, even 0.2mm deviation can affect ball trajectory.

Flatness Control Process Includes:

- Multi-stage surface grinding

- Cross-direction calibration

- Thickness equalization

- Manual inspection

- Straight-edge verification

High-end factories use large-format grinding machines to ensure:

- Uniform surface consistency

- Seam compatibility between pieces

- No micro high/low points

This is what separates professional slate from ordinary stone.

5. Load-Bearing and Structural Stability Analysis

A 12ft snooker slate set weighs approximately 1000 kg.

The slate must:

- Withstand continuous frame pressure

- Resist flexing across central span

- Maintain plane stability over years

Low-density slate may:

- Crack during installation

- Develop long-term sagging

- Produce uneven ball roll

That is why geological density is a critical factor.

6. Geological Characteristics of High-Grade Snooker Slate

Premium 45mm snooker slate typically features:

✔ Fine grain structure

✔ Uniform mineral composition

✔ Minimal internal fissures

✔ Strong compressive strength

✔ Excellent machinability

Regions known for producing suitable billiard slate have stable geological formations that allow consistent extraction of thick blocks.

Large, crack-free raw blocks are essential for 45mm thickness production.

7. Common Manufacturing Problems in Low-Quality 45mm Slate

Professional buyers should watch for:

- Thickness inconsistency between pieces

- Uneven grinding marks

- Internal hairline cracks

- Poor pocket CNC accuracy

- Surface waviness

- Weak packaging causing breakage

These problems increase installation difficulty and damage brand reputation.

8. Installation Considerations for 45mm Snooker Slate

Correct installation is as important as manufacturing.

Key Installation Steps:

- Frame leveling

- Individual slate positioning

- Precision alignment

- Seam filling (wax or resin)

- Final leveling adjustment

- Cloth covering

Because of heavy weight, proper structural support is mandatory.

9. How to Evaluate a 45mm Snooker Slate Supplier

If you are sourcing for tournament tables, verify:

Quarry Resource Stability

Consistent geological supply ensures long-term quality consistency.

Block Size Capability

Can they extract large blocks suitable for 45mm cutting?

Grinding Equipment Scale

Do they use large-format surface grinders?

CNC Precision

Are pocket openings and bolt holes precisely machined?

Quality Inspection Process

Do they test flatness piece by piece?

Export Packing

Is the slate packed with reinforced wooden crates and shock protection?

For 45mm slate, supplier capability matters more than price.

10. Why 45mm Snooker Slate Defines Professional Standard

Professional snooker demands:

- Perfect ball roll

- Zero surface distortion

- Long-term dimensional stability

- Structural integrity under heavy load

Only high-density, precision-ground 45mm slate can deliver these conditions.

For manufacturers targeting:

- International tournaments

- Premium clubs

- High-end residential markets

45mm snooker slate is the foundation of product credibility.

Frequently Asked Questions

Is 45mm slate necessary for snooker?

For 12ft full-size tables, yes. It ensures structural and performance standards.

Can 30mm slate be used for snooker?

Not for professional 12ft tables. It lacks structural rigidity.

How heavy is 45mm snooker slate?

Approximately 900–1100 kg per full set.

How long does 45mm slate last?

When properly installed, decades without structural deformation.

Final Technical Summary

45mm snooker slate is not just a thickness specification.

It represents:

- Engineering precision

- Geological quality

- Manufacturing capability

- Long-term performance reliability

For professional snooker tables, it remains the global technical benchmark.